This article explores how ceramic substrates—particularly Aluminum Nitride (AlN) and Alumina (Al₂O₃)—are transforming high-power electronics. It compares their thermal conductivity, electrical insulation, and mechanical stability, and explains why ceramic substrates are now widely used in IGBT modules, power inverters, and EV control units. Emphasis is placed on their role in managing heat and improving long-term reliability.

A comparative guide to Direct Bonded Copper (DBC) and Active Metal Brazed (AMB) ceramic substrate technologies. The article breaks down their structural differences, bonding techniques, temperature resistance, and use cases in fields like aerospace, industrial drives, and renewable energy systems. A practical selection matrix is included to help engineers choose based on thermal load and mechanical stress.

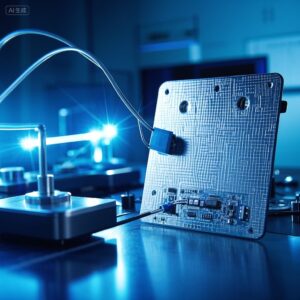

This post highlights the benefits of AlN ceramic substrates, including exceptional thermal conductivity (>170 W/m·K) and low dielectric loss. It examines use cases in high-brightness LEDs, RF modules, and laser diodes, while also touching on manufacturing challenges such as surface roughness control and metallization compatibility.